This article originally appeared in the September 2000 issue of Internet Modeler.

"The

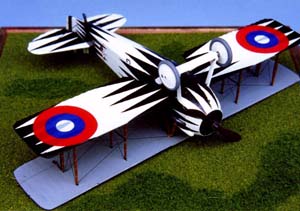

Showbirds" - Ben Casey's 'Zig-Zag'

"The

Showbirds" - Ben Casey's 'Zig-Zag'

DML 1/48 SPAD XIII

by Ernest Thomas

Introduction

Being rather fond of colorful aircraft, I tend to build a lot of WWI German models. So when Bob Pearson emailed me a page of very colorful Spad profiles, I jumped at the chance to build a non-German bird in such crazy plumage. As the first of what I hope will be a series of models, I chose Lt. Ben 'Casey' Jones' mount, sporting a striking black and white 'Splinter' scheme. For the kit, the obvious choice was the excellent DML offering. It's the best 1/48 Spad XIII available. And having built this kit twice before, I knew where to expect trouble and was prepared to deal with it. There's not a lot of trouble, but it's there.

The Cockpit

The

cockpit is first rate, straight out of the box. Just about everything

that's in the real plane is included in this kit. The only things missing

are bracing, control, and instrument wires, which I'm glad DML didn't

try to mold in – I would have had to remove it and ruin the excellent

detail.. It's also missing a piece of plumbing for from where a fuel tank

would go behind the seat. There's no fuel tank either but you can't see

back there anyway.

The

cockpit is first rate, straight out of the box. Just about everything

that's in the real plane is included in this kit. The only things missing

are bracing, control, and instrument wires, which I'm glad DML didn't

try to mold in – I would have had to remove it and ruin the excellent

detail.. It's also missing a piece of plumbing for from where a fuel tank

would go behind the seat. There's no fuel tank either but you can't see

back there anyway.

First step after cleaning all the parts is to start painting the sidewalls of the cockpit. A Spad cockpit is made up of wood structure with linen covering, some ply, and sheet metal panels, as well as a few steel tube members. For the structure, I use a medium reddish brown. Humbrol 62, in this instance. Plywood panels were Humbrol Wood, with metal panels painted a dark olive. For clear doped linens, I use whatever cream color I have handy, Humbrol 103 being a favorite. The variety of colors makes things more interesting to look at.

After

everything is painted, I then add the bracing wires on the sidwalls, made

from .006 brass wire dipped in "Blacken-it", which is a product that blackens

metal. It can be found in the model RR section of the hobby shop. All

the side wall detail parts are attached next. These include the throttle,

compass, mageneto, and wires that run from under the instrument shelf,

forward to the engine. I then built the floor panel/seat/controls assembly

as directed, doing nothing more that adding two bits of brass rod to make

up for the missing fuel lines and wires running from the rudder bar towards

the back of the plane.. Also, you must cut the tip off the top of the

fuel fill pipe (part B20) or it will cause trouble when trying to fit

B27 and A8 together.

After

everything is painted, I then add the bracing wires on the sidwalls, made

from .006 brass wire dipped in "Blacken-it", which is a product that blackens

metal. It can be found in the model RR section of the hobby shop. All

the side wall detail parts are attached next. These include the throttle,

compass, mageneto, and wires that run from under the instrument shelf,

forward to the engine. I then built the floor panel/seat/controls assembly

as directed, doing nothing more that adding two bits of brass rod to make

up for the missing fuel lines and wires running from the rudder bar towards

the back of the plane.. Also, you must cut the tip off the top of the

fuel fill pipe (part B20) or it will cause trouble when trying to fit

B27 and A8 together.

Once

all the sub-assemblies are built and painted, it's time to close the fuselage,

which goes off without a hitch. It doesn't even need much putty if you're

careful about the alignment of the two halves. The instrument shelf (part

B27) is one of the little problems. It's too thick and causes problems

fitting the top decking for the guns and cockpit opening (part A8). But

you only need to bevel the side edges from the underside get a good fit.

After that, you just assemble as directed and paint it.

Once

all the sub-assemblies are built and painted, it's time to close the fuselage,

which goes off without a hitch. It doesn't even need much putty if you're

careful about the alignment of the two halves. The instrument shelf (part

B27) is one of the little problems. It's too thick and causes problems

fitting the top decking for the guns and cockpit opening (part A8). But

you only need to bevel the side edges from the underside get a good fit.

After that, you just assemble as directed and paint it.

The shelf, and the panel(B28) are made of wood on the real bird. I painted them three different shades of brown and red/brown, with brass switches and grey bolts on the raised bit on B27. The photo etched instruments were painted black, then lightly sanded to remove the black paint from the raised bezels while leaving the recessed faces black.

When

the glue and paint are dry, proceed with the assembly according to the

instructions. There's no real big surprises or traps from here on out,

but there are a few things worth knowing about.. The headrest cushion

is too small so I made one from sheet styrene. Also, on the PE spent shellcase

chutes, don't forget to remove one of the end tabs before you try and

fold it into the box shape. I completely missed that little detail on

the instructions the first time I built this model and ended up scratch

building them.

When

the glue and paint are dry, proceed with the assembly according to the

instructions. There's no real big surprises or traps from here on out,

but there are a few things worth knowing about.. The headrest cushion

is too small so I made one from sheet styrene. Also, on the PE spent shellcase

chutes, don't forget to remove one of the end tabs before you try and

fold it into the box shape. I completely missed that little detail on

the instructions the first time I built this model and ended up scratch

building them.

The tail plane assembly goes without a hitch, but the lower wing, chin piece(part A9) and top decking(part A8) all need a bit of filler around the seams. I used a needle to apply small amounts of CA directly into the seams, being careful to avoid putting too much and the risk of sanding away the detail when trying to remove any excess.

A

few words on the photo-etch parts are in order. The exhaust pipe brackets(parts

MA21) fit in their slots like a glove, so put these on before any painting

is done on the outside fuselage. Same for the side grills(parts MA3/MA4),

chin grill?(part MA30) and the rudder control horns(parts MA20) I also

find all those little rigging attach brackets are too overscaled and didn't

use them. Same for the PE cabane rigging (parts MA17/MA18) . They're just

so much thicker than the .006 wire I use for the rest of the rigging.

And finally, the 'H' struts. I have no idea why they were done in PE.

It's clear from the quality of all the other plastic parts that DML could

have made better ones in plastic. But being PE, they're just too flat

when viewed from head on. The portions on either side of the cross members

will have to be thickened with white glue or CA to match the outboard

mainplane struts. This is also true for the foremost Cabane members (parts

MA5). I also don't know why DML put those little tabs sticking out the

tips of the 'H' struts, but the slots that they fit in on the wings are

too shallow and make the tabs stick up, and none of my references show

anything like that on the real aircraft. So they should be removed. Then

the oversized slots have to be filled around the struts. It's all a big,

unnecessary headache that could have been avoided with plastic 'H' struts.

A

few words on the photo-etch parts are in order. The exhaust pipe brackets(parts

MA21) fit in their slots like a glove, so put these on before any painting

is done on the outside fuselage. Same for the side grills(parts MA3/MA4),

chin grill?(part MA30) and the rudder control horns(parts MA20) I also

find all those little rigging attach brackets are too overscaled and didn't

use them. Same for the PE cabane rigging (parts MA17/MA18) . They're just

so much thicker than the .006 wire I use for the rest of the rigging.

And finally, the 'H' struts. I have no idea why they were done in PE.

It's clear from the quality of all the other plastic parts that DML could

have made better ones in plastic. But being PE, they're just too flat

when viewed from head on. The portions on either side of the cross members

will have to be thickened with white glue or CA to match the outboard

mainplane struts. This is also true for the foremost Cabane members (parts

MA5). I also don't know why DML put those little tabs sticking out the

tips of the 'H' struts, but the slots that they fit in on the wings are

too shallow and make the tabs stick up, and none of my references show

anything like that on the real aircraft. So they should be removed. Then

the oversized slots have to be filled around the struts. It's all a big,

unnecessary headache that could have been avoided with plastic 'H' struts.

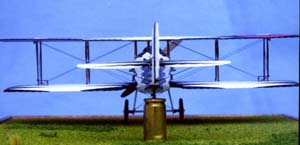

And

since we're now talking about struts, I must say that the cabane struts

are perhaps the most well designed struts I've ever seen on a model biplane.

Same for the undercarriage struts. The positive, solid attach points make

it simple to get a strong and straight assembly. And that makes attaching

the top wing a snap. The joint where the undercarriage struts attach to

the spreader bar(part A13) need a bit of filling and sanding, but it's

a sturdy assembly which makes it easy to fix.

And

since we're now talking about struts, I must say that the cabane struts

are perhaps the most well designed struts I've ever seen on a model biplane.

Same for the undercarriage struts. The positive, solid attach points make

it simple to get a strong and straight assembly. And that makes attaching

the top wing a snap. The joint where the undercarriage struts attach to

the spreader bar(part A13) need a bit of filling and sanding, but it's

a sturdy assembly which makes it easy to fix.

At this point, every thing just sorta falls together. The top wing rest securely on the cabanes and the mainplane struts can be popped into place after the wing is secured to the cabanes. When attaching the aileron linkage, it's best to attach parts MA11/MA12 to the top wing and then fitting parts MA31 in place. And that's about all I can say on building this model.

Painting

This

model was painted in my typical manner for a biplane. The model was assembled

almost up to the point of attaching the top wing, less wheels, prop, skid,

guns, windscreen, pipes, etc... I then mask off the cockpit opening and

sprayed the entire model white. All the black splinters were cut from

black decal film. It really was pretty simple. After the entire model

was splintered, I applied a clear coat and proceeded with final assembly.

This

model was painted in my typical manner for a biplane. The model was assembled

almost up to the point of attaching the top wing, less wheels, prop, skid,

guns, windscreen, pipes, etc... I then mask off the cockpit opening and

sprayed the entire model white. All the black splinters were cut from

black decal film. It really was pretty simple. After the entire model

was splintered, I applied a clear coat and proceeded with final assembly.

I would like to thank Bob Pearson, Dale Beamish, Lance Kriege, Steve Perry and Mike DiCianna for their invaluable assistance on this project.