This article originally appeared in the April 1999 issue of Internet Modeler.

A Soviet

Sopwith

A Soviet

Sopwith

Toko's 1/72 Snipe

by Michael Kendix

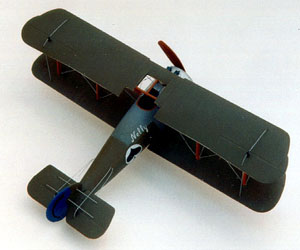

Lately, Toko has brought a number of 1/72nd scale World War One model kits to market. Reasonable in price, most can be purchased for less than $10; the Sopwith 7.F1 Snipe is among these, giving modelers an opportunity to build either a British World War One or Soviet early post-revolutionary period version. The Snipe legend was born on October 27 1918 when Major William Barker earned the Victoria Cross for shooting down four Fokker D.VIIs. Appearing in the First World War theater for the first time on September 23 1918, the Snipe was a late entrant into the war and continued to be used by the RAF until 1927. In that time, three Snipes were used by the Soviet Union during the early post-revolutionary period, when the nascent Soviet state was at war with Poland. On May 29 1920 Georgy Stepanovich Sapozhnikov of the Soviet Red Air Fleet was credited with shooting down Polish pilot Stefan Pawlikowski, an accomplishment that earned him the Order of the Red Banner. His colors are shown in the accompanying profile. A picture of his aeroplane can be found in Lennart Andersson's "Soviet Aircraft and Aviation 1917-1941"; the subject of this model.

THE KIT

I measured the kit's pieces against the 1/72nd scale

diagram from Windsock Datafile 46. The pieces are almost spot-on for the

"Late Model" version, with the possible  exception

that the tail-fin might be slightly undersized but the difference is exceedingly

small.

exception

that the tail-fin might be slightly undersized but the difference is exceedingly

small.

The kit looked good on the sprue with only a small amount of clean up necessary due to molding flash. The parts required hardly any sanding and smoothing; an easy job. The manufacturers provided two sets of decals but the British RAF roundels are hopeless; the inner red discs are tiny, almost dots, whilst the outer blue circles are too dark and too big. There is no room to use a stencil to correct the red "dots" because the blue outer rings are too wide. If you decide to make the RAF version, you should consider obtaining a new set of roundels and matching rudder decals.

PRECONSTRUCTION

Using a #80 drill bit, I drilled holes through the struts' ends, through which I intended to pull the rigging later in the assembly process. I also drilled the holes for the rigging in the fuselage, and the landing gear's fixed spreader and tail pieces. A king-post is not provided in the kit but you could add this feature; this would require further drilling for the associated rigging.

COLORS

My

next task was to decide upon the color scheme and mix the paints. I recognize

that there are some paints provided on the market, which purport to replicate

Clear Doped Linen (CDL) and Protective Colouring Number 10 (PC-10), however,

there appears to have been some significant variation in shades, and no

consensus exists on the exact colors used, especially for PC-10. I find

it easier to mix the colors rather than search for the exact shade in

my local hobby stores or in mail order catalogues. Using the profile supplied

by Bob Pearson, I forged ahead. PC-10 was three parts Model Master's Dark

Earth and one part Floquil British Dark Green. The CDL was five parts

Model Master's Sand, 1 part Model Master's Insignia Yellow, and one part

Model Master's Dark Earth. The inside of the fuselage was painted PC-10,

and the cockpit interior was painted wood brown.

My

next task was to decide upon the color scheme and mix the paints. I recognize

that there are some paints provided on the market, which purport to replicate

Clear Doped Linen (CDL) and Protective Colouring Number 10 (PC-10), however,

there appears to have been some significant variation in shades, and no

consensus exists on the exact colors used, especially for PC-10. I find

it easier to mix the colors rather than search for the exact shade in

my local hobby stores or in mail order catalogues. Using the profile supplied

by Bob Pearson, I forged ahead. PC-10 was three parts Model Master's Dark

Earth and one part Floquil British Dark Green. The CDL was five parts

Model Master's Sand, 1 part Model Master's Insignia Yellow, and one part

Model Master's Dark Earth. The inside of the fuselage was painted PC-10,

and the cockpit interior was painted wood brown.

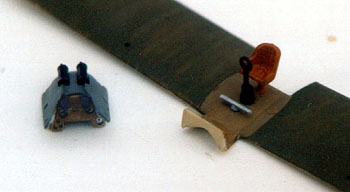

INSTRUMENT PANEL

One of the minor disappointments in this kit is that

the instrument panel does not  contain

the details depicted in the instruction sheet; it is totally flat and

contains no detail whatsoever. I decided to add detail by drilling holes

to simulate the instrument dials, copying the pattern of dials printed

on the instruction sheet. A #68 bit was used for the two lower left hand

side holes, a 72 bit for the left hand side dials above those, various

other slightly larger sizes for the other dials. I then cut some clear

thin .005 Evergreen sheet the same size and shape of the instrument panel,

painted it white, and attached it to the rear of the instrument panel.

The "white dials" showed through and I added a few details to the dials

using a 'Papermate' "Plastic Point", which gave the dials a slightly more

realistic appearance. These details were difficult to see when the fuselage

was closed, and when the top wing was in position, the panel was virtually

invisible without the proverbial "penlight and dental mirror".

contain

the details depicted in the instruction sheet; it is totally flat and

contains no detail whatsoever. I decided to add detail by drilling holes

to simulate the instrument dials, copying the pattern of dials printed

on the instruction sheet. A #68 bit was used for the two lower left hand

side holes, a 72 bit for the left hand side dials above those, various

other slightly larger sizes for the other dials. I then cut some clear

thin .005 Evergreen sheet the same size and shape of the instrument panel,

painted it white, and attached it to the rear of the instrument panel.

The "white dials" showed through and I added a few details to the dials

using a 'Papermate' "Plastic Point", which gave the dials a slightly more

realistic appearance. These details were difficult to see when the fuselage

was closed, and when the top wing was in position, the panel was virtually

invisible without the proverbial "penlight and dental mirror".

The front of the fuselage is not exactly as pictured

in the kit's diagram instructions since it leaves two small triangular

gaps. I was unable to ascertain whether this was  correct

or not. In any event, once assembled, this is not something that can be

seen without extremely close inspection; and it is fairly straightforward

to fill these spaces with thin card and putty. The fuselage sits on the

lower wing, with the cockpit seat and control stick mounted directly on

the lower wing piece. The seat was painted wood brown, the foot rudder

was painted aluminum and the control stick was painted black. After the

cockpit was completed, I joined the fuselage sides (the fuselage is split

vertically) and used 'Squadron White' for the lower and 'Squadron Green'

for the top cracks.

correct

or not. In any event, once assembled, this is not something that can be

seen without extremely close inspection; and it is fairly straightforward

to fill these spaces with thin card and putty. The fuselage sits on the

lower wing, with the cockpit seat and control stick mounted directly on

the lower wing piece. The seat was painted wood brown, the foot rudder

was painted aluminum and the control stick was painted black. After the

cockpit was completed, I joined the fuselage sides (the fuselage is split

vertically) and used 'Squadron White' for the lower and 'Squadron Green'

for the top cracks.

The cowl, and engine were then added. The engine was painted black and the "spokes" were painted aluminum. The cowl and front panels were painted aluminum and the mid panels painted British Ocean Grey, as shown in Bob Pearson's profile. The tail was painted blue using Humbrol 25. Gluing the fuselage together presented a challenge because the parts do not quite fit unless you do it perfectly first time. The front top piece containing the gun mounts is separate and this is problematic since it affords the opportunity of not getting the fuselage glued just right. On the other hand, it permits easy painting of the panelling; you don't need to mask it because it's separate.

ATTACHING THE WINGS

The next task was to attach the top wing; always one

of the more challenging tasks when building a biplane. This is especially

the case for this model since it is relatively  small

but contains four interplane struts on each side. The front and rear interplane

struts are not identical, so it was necessary to remember which struts

were associated with the front and back. Having glued the interplane struts

in place, and achieved the correct angle for these struts, I found the

forward cabane struts to be too short. This may have been due to a building

error on my part, however, replacing them using strips of Evergreen StripStyrene

was not too difficult, gradually shortening the strips until they fitted

into place. I then made the Venturi-form exhauster for the Badin petrol

system, which is situated on the starboard forward center-section strut.

This was not problematic; I used a small piece of .020 Evergreen styrene

rod. Ideally, this exhauster should look like two cones with their sharp

ends placed next to each other but given the small scale of this kit,

I passed on that particular level of detail. Regardless, it looks better

than the kit version since the kit makes the exhauster as part of the

strut, when in reality the exhauster is attached to the outside of the

strut.

small

but contains four interplane struts on each side. The front and rear interplane

struts are not identical, so it was necessary to remember which struts

were associated with the front and back. Having glued the interplane struts

in place, and achieved the correct angle for these struts, I found the

forward cabane struts to be too short. This may have been due to a building

error on my part, however, replacing them using strips of Evergreen StripStyrene

was not too difficult, gradually shortening the strips until they fitted

into place. I then made the Venturi-form exhauster for the Badin petrol

system, which is situated on the starboard forward center-section strut.

This was not problematic; I used a small piece of .020 Evergreen styrene

rod. Ideally, this exhauster should look like two cones with their sharp

ends placed next to each other but given the small scale of this kit,

I passed on that particular level of detail. Regardless, it looks better

than the kit version since the kit makes the exhauster as part of the

strut, when in reality the exhauster is attached to the outside of the

strut.

UNDERCARRIAGE

Next

I assembled and attached the landing gear. This was straightforward but

I had to drill two new holes for the forward struts since they did not

reach exactly far enough forward to the extant holes. This is probably

a design fault in the model since there is no opportunity for me to have

affected this fit during construction. I was then faced with a choice;

either replace the landing gear struts or drill new holes for the landing

gear. I chose the latter since the distance was less than 2 millimeters

and I filled in the old gaps with Squadron White putty.

Next

I assembled and attached the landing gear. This was straightforward but

I had to drill two new holes for the forward struts since they did not

reach exactly far enough forward to the extant holes. This is probably

a design fault in the model since there is no opportunity for me to have

affected this fit during construction. I was then faced with a choice;

either replace the landing gear struts or drill new holes for the landing

gear. I chose the latter since the distance was less than 2 millimeters

and I filled in the old gaps with Squadron White putty.

DECALS - TAKE ONE

Prior to the rigging and attaching the aileron control horns, I painted the wings surfaces with Future enamel polish in preparation for the decals and to protect the model as I attached the rigging. The black five-point star decals were placed on the underside of the lower wing; there are no decals for the upper surface of the top wing. I used Model Master Decal Set on the surface of the wing, and then used Solvaset Decal Setting Solution on top of the decal to ensure a long lasting snug fit.

RIGGING

RIGGING

I rigged the wings using "Invisible Thread". I then cut out the control horns for the tail and wing using Evergreen StripStyrene size .010 x .080", drilling through the paint before gluing the horns in place with CA glue. Adhering the control horns to the plastic, rather than the paint on top of the plastic, seems to provide a stronger bond. Using this method, I find the control horns do not detach as often when the rigging is tightened. The rest of the model was then rigged using the same "Invisible Thread".

DECALS - TAKE 2

The decals for the tail and the fuselage were then attached. The tail decals proved somewhat tricky due to their shape and the difficulty of positioning them on the rudder, but with a little patience, I was able to move them into position.

FINAL TOUCHES

A few touch ups and I was ready to spray on a couple

of coats of 'Model Master Lacquer Overcoat Lusterless (Flat)' from the

aerosol can. A semi-gloss version of this  product

is also available for those who prefer the "newer look". Since I do not

possess an airbrush, the Lusterless Flat coating really helps provide

a nice surface to the model, and also helps to prevent the decals from

peeling off.

product

is also available for those who prefer the "newer look". Since I do not

possess an airbrush, the Lusterless Flat coating really helps provide

a nice surface to the model, and also helps to prevent the decals from

peeling off.

SUMMARY

In summary, this kit is a satisfying model to build. The parts fit together tolerably well, it is within the capacity of a relatively inexperienced modeler, and requires no aftermarket components to produce a realistic model of the original aeroplane. I recommend it.

THANKS TO:

Dave Vosburgh and Bob Pearson for both advice and references.

REFERENCES:

Windsock Datafile No.46: THE SOPWITH SNIPE by J M

Bruce

SOVIET AIRCRAFT AND AVIATION 1917-1941 by Lennart

Andersson

RED STAR SNIPES by Colin Owers; Windsock Magazine

Vol.10 No.4.